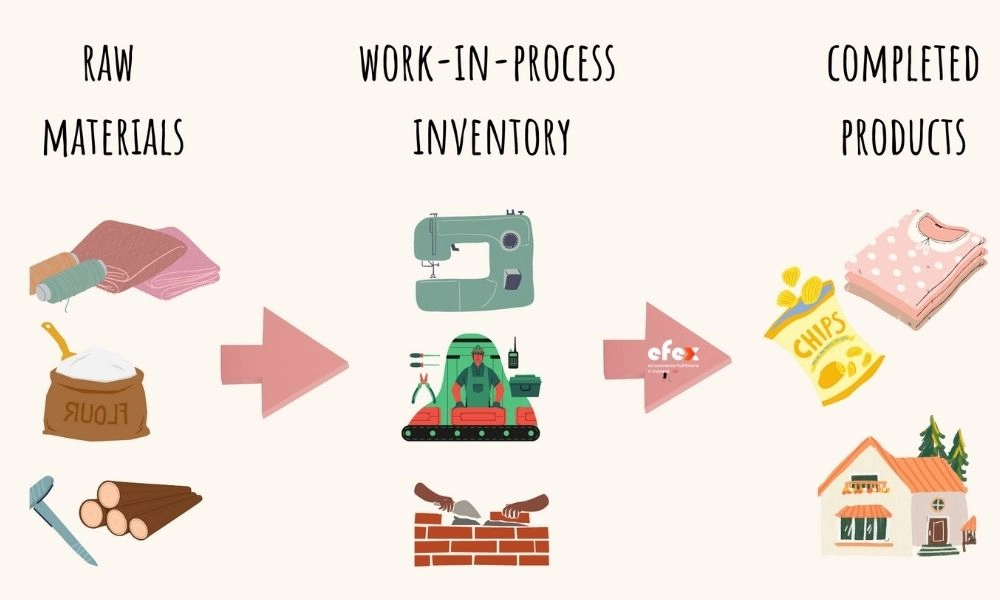

WIP (Work In Progress), also known as work in progress, is an important concept in production management and project management. WIP represents the amount of work or products that are in progress but not yet completed. Understanding what is WIP and applying roles and methods to reduce WIP not only helps increase work efficiency but also improves product and service quality.

What is WIP?

WIP is a term used to refer to products, tasks or projects that are in production but not yet completed. This includes all stages from the beginning to the final product. WIP can be present in many fields, from industrial manufacturing, to software, to customer service.

In manufacturing, WIP are unfinished products, from machine parts, electronic components to consumer products. In the software industry, WIP is code that is being written or tested. In customer service, WIP can be support requests that are being processed.

The role of WIP in management

WIP plays an important role in production and project management. Some key roles of WIP include:

Evaluate work progress

WIP helps managers evaluate the progress of tasks and projects. By tracking WIP, they can see how much work has been completed, how much is still in progress, and what problems may be encountered in the production process.

Manage resources effectively

WIP provides information to manage resources more effectively. By knowing the amount of work in progress, managers can appropriately adjust manpower, materials, and time to avoid waste and optimize work processes.

Improve product quality

Tracking and managing WIP helps detect errors and omissions early in the production process. This helps improve product quality and minimizes the risk of having to repair or rework the product.

Enhance the ability to meet customer needs

Effective WIP management helps businesses increase their ability to meet customer needs. When WIP is well controlled, production times are reduced, delivery times are faster, and the ability to respond to urgent requests is increased.

Effective method to reduce WIP

Reducing WIP is one of the important goals of many businesses to optimize production processes and improve working efficiency. Here are some common methods to reduce WIP:

Apply Lean Manufacturing method

Lean Manufacturing is a production management method that optimizes processes by eliminating waste and unnecessary waste. The fundamentals of Lean include Just-In-Time (JIT), Kaizen (continuous improvement), and 5S (organize, clean, create, prepare, set in order).

- Just-In-Time (JIT)

JIT is a production management method that minimizes inventory and WIP by producing goods only when requested by customers. This helps reduce inventory costs and optimize production processes.

- Kaizen

Kaizen is a continuous improvement method that encourages everyone in the organization to contribute ideas to improve work processes. By applying Kaizen, businesses can continuously find and eliminate waste in the production process, thereby reducing WIP.

- 5S

5S is a workplace management method that includes the steps: arrangement, cleanliness, creativity, readiness, and order. Applying 5S helps create a neat, tidy, and efficient working environment, thereby reducing WIP.

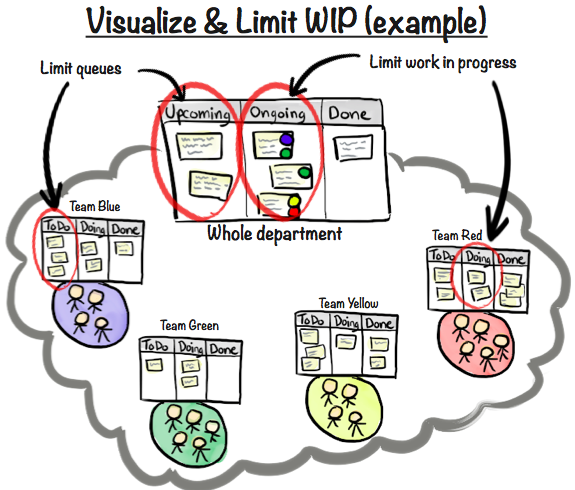

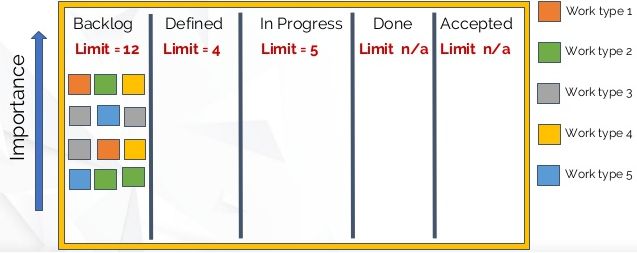

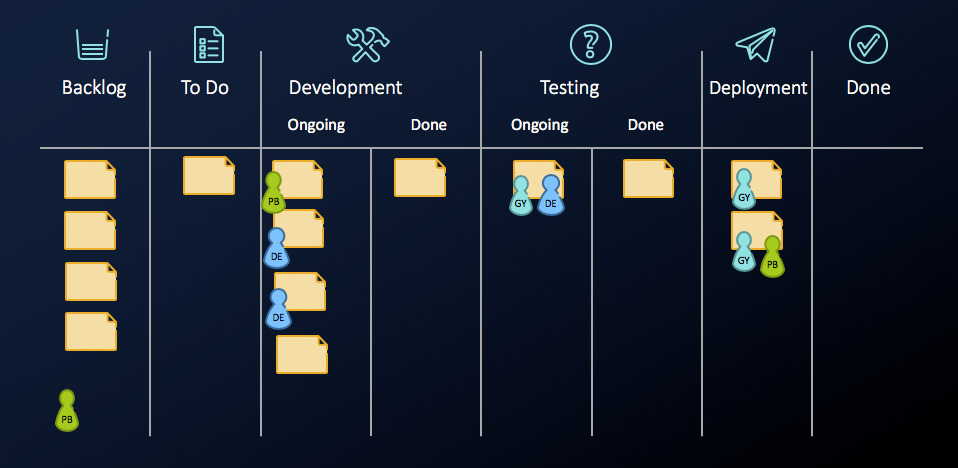

Use Kanban

Kanban is a visual work management method that helps track and control WIP through Kanban cards and Kanban boards. The Kanban board shows work in progress through columns such as “To Do”, “In Progress”, and “Done”. Limiting the number of jobs in each column helps control WIP and prevent overload.

Deploy an advanced production management system

Advanced production management systems such as Manufacturing Execution System (MES) help monitor and manage the production process effectively. MES provides real-time information about the status of jobs, helping managers easily control and reduce WIP.

Human resource training and development

Training and development of human resources is an important factor in reducing WIP. When employees are well-trained and have effective working skills, they will complete work faster and with higher quality, thereby reducing WIP. Training programs may include courses in technical skills, time management skills, and teamwork skills.

Improve workflow

Improving workflow is one of the important methods to reduce WIP. Businesses should regularly review and improve work processes to eliminate unnecessary steps and increase efficiency. This can include automating processes, optimizing processes, and adopting new technologies.

Enhance collaboration and communication

Enhancing collaboration and communication between departments within the business is also an effective method to reduce WIP. When departments coordinate well with each other, work will be done more smoothly, avoiding waiting and interruptions. Adopting modern project management and communication tools like Slack, Trello, or Asana can help improve collaboration and communication.

Benefits of reducing WIP

Reducing WIP brings many benefits to businesses, including:

Increase work efficiency

When WIP is well controlled, employees will focus on completing current work instead of having to handle multiple tasks at the same time. This helps increase work efficiency and reduce stress for employees.

Improve product quality

Reducing WIP helps detect and fix errors early in the production process, thereby improving product quality and reducing the rate of defective goods.

Reduce production costs

When WIP is controlled, businesses will reduce inventory costs, labor costs, and other related costs. This helps optimize resources and increase profits.

Enhance the ability to meet customer needs

Reducing WIP helps reduce production and delivery times, thereby enhancing the ability to meet customer needs and improve customer satisfaction.

Enhance competitiveness

Businesses that are able to control and reduce WIP will become more flexible and agile in meeting market needs, thereby enhancing competitiveness.

WIP is an important element in production and project management. Understanding and effectively managing WIP not only helps increase work efficiency but also brings many other benefits such as improving product quality, reducing production costs, and enhancing the ability to meet customer needs. . By applying the methods that Proxyv4.net shared above, businesses can effectively reduce WIP, thereby improving operational efficiency and competitiveness in the market.